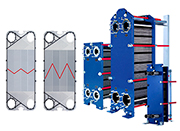

Wide-gap Plate Heat Exchanger is adopted the design structure of coarse ripples. There are some “S” runners between plates and no completely metal contact, it applies to high viscosity medium with Solid, crystal, fiber, slurry material, it is suitable for special working condition which V-shape corrugated plates cannot apply to. And it is can be widely used in sugar, paper, and food and fruit juice industries because it has excellent heat exchange performance and easy to disassemble, clean and maintain.

BOGE’s unique wide gap exchangers are specially suited for media containing fibres, solids, particles as well as for fluid with highly viscous which may block traditional plate heat exchangers. The wide gaps of up to 12mm, the no metallic contact point plate pattern allow fibres and solids to easily pass through heat exchangers.

Available gap sizes for this model are:

-Wide/Narrow 12mm/6mm

-Wide/Wide 5mm/5mm

Benefits

-Recovery more heat, reduce your energy costs.

Heat sources can be utilized that were previously seen as waste heat such as fermented mash cooler, molasses cooler ect,.

-Maximize process uptime

With Free Flow, service intervals are longer because fouling is minimized.

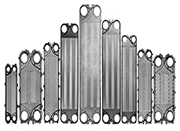

-Lightweight, less space

High thermal efficiency makes Free Flow very compact compared with shell & tube or spiral heat exchangers.

-Expand with your plant

Typical Applications

-Biochemistry and Pharmaceutical

fermented mash, liquefied mash, starch milk, waste water

-Sugar

molasses, mixed juice, clarified juice, thin juice

-Pulp and Paper

waste water

-Petrochemicals

-Food and Beverage

180 2027 5881

180 2027 5881