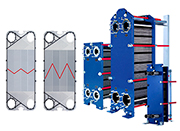

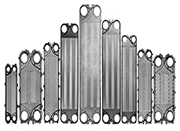

The Semi-welded Plate Heat Exchanger is particularly offered for heating and cooling of aggressive media. Two corrugated plates are positioned back to back and welded together as "cassette" by laser, along the sealing groove designed for the gasket of the semi welded PHE. The semi-welded plate for PHE is specially offered for aggressive media. Generally, two pieces of PHE stainless steel plates are welded back to back by laser along the sealing groove for the gasket to form the plate cassette. Each cassette is sealed with a gasket. The refrigerant flows from one cassette to the other, contacting with only two of the four ring gaskets at the inlet and the outlet.

BOGE semi-welded plate heat exchangers are the prime choice for challenging applications that involve aggressive media or high pressure. The semi-welded plate heat exchangers are very versatile which means that they can easily be configured for use in different industries and applications that involve challenging media, such as chemical processing.

We customize each heat exchanger according to your specifications and offer durable solutions designed to withstand extreme conditions and minimize the risks of operation.

You can safely operate with hazardous or aggressive media, high pressure, or extreme temperatures that are unsuitable for regular fully gasketed heat exchangers. We design to give you peace of mind.

What are the advantages of Semi-Welded Plate Heat Exchanger?

1. Wide temperature range from -38℃ to 200℃

2. Maximum design pressure up to 30 bar

3. Rigid mechanical construction

4. Outstanding leakproofness for high safety

5. Capacity in handling aggressive media

6. Adjustable size, compact structure, small space

Applications

HVAC industry

Marine/offshore industry

Dairy/food/beverage industry

Sugar industry

Pulp and paper industry

Heavy industry

Mining industry

Petrochemical industry

Chemical industry

Evaporation and condensing duties

High pressure liquid/liquid applications

180 2027 5881

180 2027 5881